rockwell hardness test questions|rockwell hardness test theory : inc The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .

1 dia atrás · Resultado da Lotomania, concurso 2590, hoje, quarta-feira, 28 de fevereiro de 2024 (28/02/24).Prêmio é de R$ 3,2 milhões. Os números foram sorteados pela Caixa .

{plog:ftitle_list}

23 de jan. de 2023 · Vila Andrade, São Paulo-SP. Telefone: (11) 3502.6200. WhatsApp: (11) 97201.5678. Navegação de posts. Estímulo de colágeno Benefícios do Retinol. A Toxina .

This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Rockwell Hardness Test”. 1. Which hardness test is most widely used in the US? a) Brinell. b) Vickers. c) Shore. d) Rockwell. View Answer. 2. .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .

publicly available iihs rear impact test

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inverselyIndentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the .

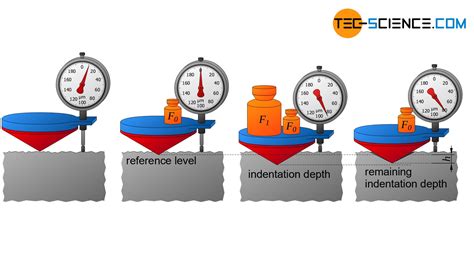

The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative .

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely proportional to the hardness. . VIVA QUESTIONS: 1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness. . If you have any questions about this publication or are having problems accessing it, please contact [email protected]. Created January 1, 2001, Updated February 24, 2009Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .Answer: a Explanation: Brinell hardness test uses a hardened steel ball as an indenter. It is 10 mm diameter ball. Diamond indenter is used in the Rockwell test.

Hardness. Hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. Rockwell hardness test. Rockwell hardness testing is a general method for measuring the bulk hardness of metallic and polymer materials. Rockwell hardness testing is an indentation testing method.

The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic ScalesThe indenter used in C-scale of Rockwell hardness test is named _____ a) CABAL b) BRALE c) BRALL d) IDOL View Answer. . Mechanical Metallurgy Questions and Answers – Hardness Test – Microhardness Test ; Aerospace Materials and Processes Questions and Answers – Aircraft Materials – Hardness testing – Vickers and Shore Scleroscope .Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic. . Mechanical Properties and Testing | Interview Question and Answers Tensile Test – Purpose , Graph , Results , .

Rockwell hardness test, as a measure of the resistance of a material to localized plastic deformation, is a valuable and widely used mechanical test. However, the accuracy of Rockwell hardness measurement is still in question. The indenter, including both the spheroconical diamond indenter and ball indenter, is a major contributor to Rockwell .

Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.

The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.Question: Rockwell Hardness Test Lab Object Background: The Rockwell hardness test is an indentatio To determine the hardness of metallic materials by Rockwell Hardness Tester n test which is nothing more than ndentation. The test measurement of resistance of a material to permanent i consists of forcing a steel ball or diamond cone into the . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .

Rockwell hardness test, a type of hardness test. Hardness Testing Loads. The hardness testing load is the load (“force”) that is applied to the indenter when pressing into the material being tested. The depth or size of . The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read the standard completely before .While the Rockwell hardness test has its uniqueness, its accuracy is also guided by some critical factors you need to consider before engaging in this test method. Rockwell Testing Machine – The machine itself is one critical consideration for an accurate Rockwell test result. And though the Rockwell test is often seen as very easy and quick .This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Vickers Hardness Test”. 1. _____ Indenter is used in Vickers hardness test.

pump impact test

In Rockwell hardness test, an initial minor load is applied, followed by a major load. Specimen thickness should be at least 10 times the depth of the indentation. QUESTION 15 Tensile stress is defined as the tensile force per unit cross section area.The Rockwell hardness test involves indenting the surface of a material with a diamond cone or steel ball indenter and measuring the depth of the resulting indentation. Significance of Rockwell Hardness. Rockwell hardness is significant because it is a quick and easy method of measuring the hardness of a material. It is also a reliable method .The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load.Advanced Physics questions and answers; Problem 5: 6.44. An additional Rockwell hardness test is made on the steel considered in Problem 6.43. Using a diamond cone under a load of 150 kg, an indentation of 0.157mm is found. What is the .

The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. This technique gauges how deeply an indenter presses into a material under a heavy load compared to its penetration under a lighter one.Explanation: The dial on the Rockwell hardness test method is where the value can be found. There are two sets of numbers on the dial, black and red. Before the major load is applied on the test specimen, the direct reading dial on the machine has to be fixed to zero. . Rockwell Hardness Test ; Testing of Materials Questions and Answers .

🕑 Reading time: 1 minute Hardness of a material is defined as its resistance to indentation. Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the [.]

rockwell hardness testing method

puncture & impact testing

rockwell hardness tester least count

rockwell hardness test theory

aline mineira onlyfans. subscribe (409) from: anonymous. 5 months ago 29 34:54. 90% (20 votes) categories: Amateur Anal Big Tits Cumshots European French Hardcore. tags: .

rockwell hardness test questions|rockwell hardness test theory